Seismic Isolators: What Are They? How Do They Work? Their Use and Application Areas According to the Turkish Building Earthquake Code 2018 (TBDY 2018)

Introduction

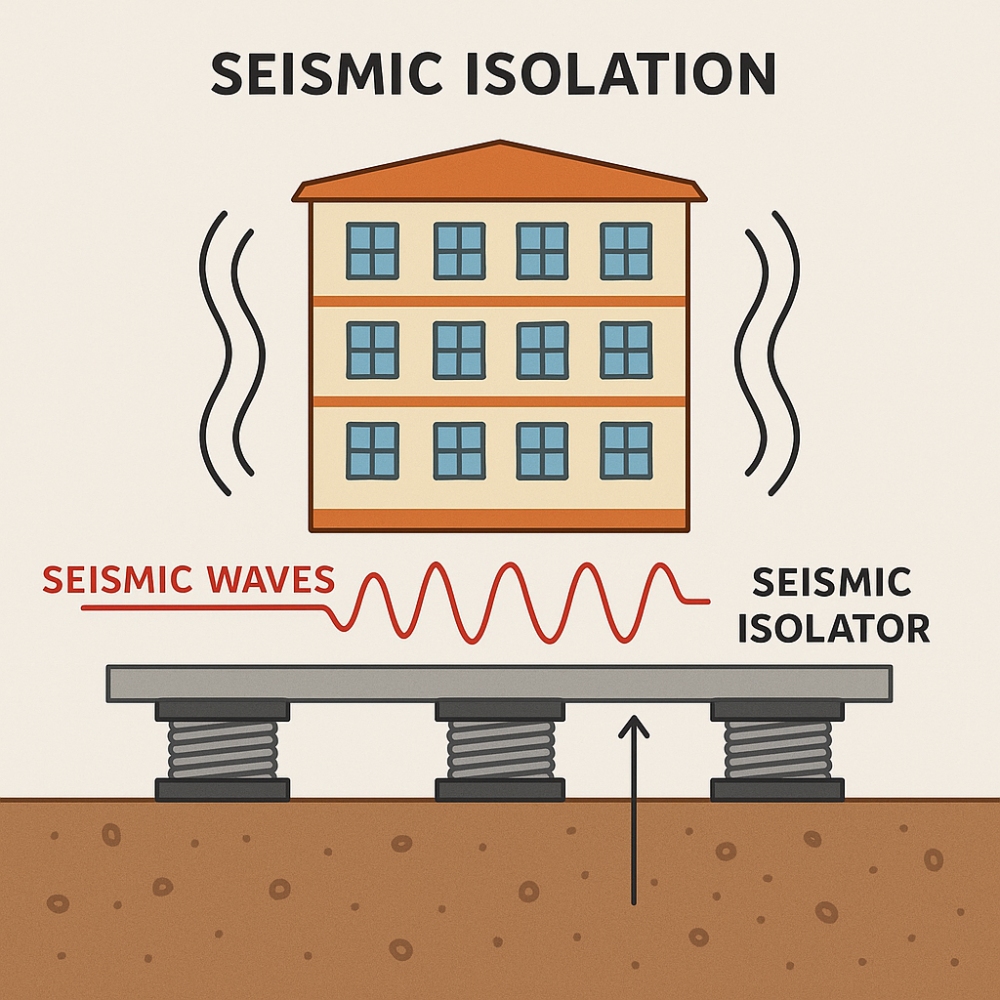

Turkey is a country with high earthquake risk, classified into different seismic zones ranging from the first to the fourth degree. For this reason, the safety and durability of buildings have become increasingly important. Earthquakes can cause serious loss of life and property by disrupting the structural integrity of buildings. However, engineering solutions developed to counter earthquakes aim to minimize these losses. One of these solutions is seismic isolators. Seismic isolators are placed at the foundation of buildings and absorb the seismic forces that occur during an earthquake, greatly reducing the transmission of these forces to the superstructure of the building. The Turkish Building Earthquake Code 2018 (TBDY 2018) regulates the use of such systems within specific rules, ensuring the construction of safe buildings. This article will detail the definition, working principle, types, usage criteria according to TBDY 2018, and application areas of seismic isolators.

1. What Are Seismic Isolators?

Seismic isolators are systems that reduce the direct connection between a building and the ground during an earthquake, protecting the structure from seismic forces. These isolators, placed at the foundation of the building, prevent the building’s movement relative to the ground and dampen horizontal movements during an earthquake. Seismic isolators isolate the building from earthquake energy, enhancing the safety of both the occupants and the contents inside the building.

1.1 Objectives

The primary objectives of seismic isolators are as follows:

• To isolate earthquake forces from the structure

• To increase the building’s period and prevent resonance effects

• To ensure the safety of lives and protect the structural integrity of the building

• To maintain the functionality of critical structures, such as hospitals, educational facilities, and data centers, after an earthquake

2. How Do Seismic Isolators Work?

Seismic isolators create a barrier against the earthquake by minimizing the interaction between the structure and the ground. This system makes the structure more flexible against horizontal movements by damping the vibrations and movements in the ground. The working of seismic isolators is based on fundamental physical principles.

2.1 Basic Physical Principles

The fundamental principles underlying the operation of seismic isolators are as follows:

• Period Extension: Isolators extend the natural vibration period of the structure, preventing the building from entering resonance. This reduces the impact of the earthquake on the structure.

• Energy Damping: Isolators dampen the earthquake energy, thereby reducing the effects on the structure. Lead-core isolators, in particular, are effective at dissipating energy.

• Controlled Movement: Isolators allow the structure to move in only specific directions. As a result, the building only experiences horizontal movements, and vertical movements are minimized.

3. Types of Seismic Isolators

Different types of seismic isolators have been developed based on soil conditions, building types, and performance objectives. These isolators provide solutions suitable for various structural needs.

3.1 Elastomeric Isolators

Elastomeric isolators are made by combining rubber and steel plates. These isolators are known for their flexible and durable properties.

• Advantages: High flexibility and long lifespan

• Disadvantages: Limited energy damping capacity

3.2 Lead Rubber Bearings (LRB)

These isolators have a lead core placed in the center of elastomeric layers, providing both energy damping and flexibility.

• Advantages: Provides both energy damping and flexibility

• Applications: Used in critical structures like hospitals, school buildings, and public buildings

3.3 Pendulum (Friction Pendulum) Bearings

These isolators consist of concave surfaces and movable components. Pendulum-type isolators are effective at handling large horizontal displacements.

• Advantages: Suitable for large displacements

• Disadvantages: High cost

3.4 Viscous Dampers

Viscous dampers are systems with viscous fluid inside them that act as shock absorbers. These isolators are particularly effective in high-rise buildings.

• Advantages: Effective in high-rise buildings

• Applications: Used in skyscrapers, bridges, and transportation structures

4. Seismic Isolation Design According to TBDY 2018

The Turkish Building Earthquake Code 2018 (TBDY 2018) defines in detail how seismic isolation systems should be used in structural design. This regulation has been created to ensure the reliability of isolator systems from both theoretical and practical engineering perspectives. The rules in the regulation cover performance objectives, structural analysis methods, and the testing and certification processes of isolator systems.

4.1 Performance Objectives

TBDY 2018 defines the performance levels targeted for buildings with seismic isolation systems to ensure their functionality after an earthquake. These objectives vary depending on the building’s intended use, and analyses must be conducted in accordance with these objectives.

• Immediate Occupancy (IO)

This performance level aims to keep the building fully functional immediately after the earthquake. It is required for critical infrastructures such as hospitals, fire stations, data centers, and emergency response buildings. The building should be able to operate at full capacity after the earthquake, with no damage to equipment and all systems remaining active.

• Limited Structural Damage (LS)

In less critical buildings, some level of damage is acceptable. The goal in such buildings is to ensure that the structure remains intact and stable without major structural deformations, prioritizing life safety. This performance level is typically preferred for educational buildings, residential buildings, and commercial structures.

The regulation mandates the selection of one of these objectives based on the building's intended use. The design process is shaped according to these objectives.

4.2 Design and Modeling Principles

TBDY 2018 requires the use of advanced analysis techniques beyond traditional methods for structural design with isolator systems. Below are the basic principles:

• Modeling Nonlinear Behavior:

Isolators exhibit nonlinear mechanical behavior, so the models used in seismic analysis should represent this behavior accurately. Parameters such as energy dissipation and rigidity changes, especially in lead-core or friction isolators, must be taken into account.

• Three-Dimensional (3D) Nonlinear Time History Analysis:

A 3D structural model of the building must be analyzed using nonlinear time history analysis. This approach provides the most accurate representation of the dynamic interaction between the structure and the isolator system.

• Seismic Ground Motion and Soil Class:

Seismic analysis should use earthquake spectra defined according to the soil class of the construction site. TBDY 2018 defines different acceleration values and frequency ranges for various soil types. Moreover, at least seven different real or synthetic earthquake records should be used in the analysis, and these records should be scaled as described in the regulation.

• Parametric Review of Isolator Mechanical Properties:

The rigidity, damping ratio, maximum horizontal displacement capacity, and other properties of the isolators directly affect the system's overall response. These parameters must be considered in calculations, and safety limits for excessive displacements should be defined.

4.3 Testing and Certification

To ensure that seismic isolators are safe, functional, and comply with the regulations, a three-stage testing and certification process is required:

-

Prototype Testing (Type Tests):

During the design phase, full-scale prototype tests should be performed on samples of the isolators. These tests assess the isolators’ performance according to criteria such as maximum displacement, stiffness changes under load, and energy damping capacity. The goal is to verify whether the design assumptions hold in the field. -

Manufacturing Process and Quality Control:

During the mass production of isolators, quality control should be conducted for each production batch. Manufacturers must document the technical specifications of each isolator and provide compliance reports. -

Factory Acceptance Tests (FAT):

Static and dynamic tests must be carried out in the factory for each isolator. These tests measure the damping coefficient, stiffness ratio, and maximum load capacity of the isolator. Test results are checked by project consultants and relevant authorities. Isolators without a compliance report cannot be shipped to the construction site.

Certification and Documentation:

Isolators that pass the tests must be certified by accredited institutions. The CE certificate is required for European Union compliance, while TSE and quality certificates from independent auditing organizations are required for applications within Turkey. In addition, compliance reports with TBDY 2018 must be included in the project files.